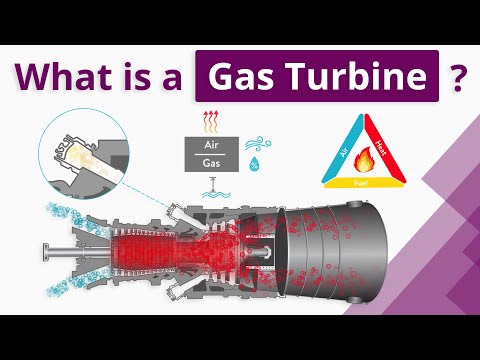

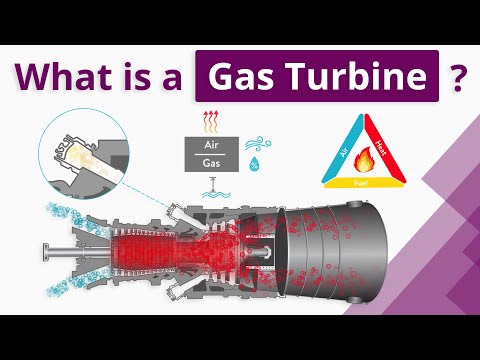

ガスタービンとは?(初心者向け) (What is a Gas Turbine? (For beginners))

陳柏志 が 2021 年 01 月 14 日 に投稿  この条件に一致する単語はありません

この条件に一致する単語はありませんUS /ˈprɑːpərli/

・

UK /ˈprɔpəlɪ/

US /ˈstrʌk.tʃɚ/

・

UK /ˈstrʌk.tʃə/

- n. (c./u.)構造;建物

- v.t.組み立てる;組織する

- n. (c./u.)群集の動き;急上昇;波や価格の急上昇

- v.i.突然ある方向に動く;思わぬところまで上昇する

エネルギーを使用

すべての単語を解除

発音・解説・フィルター機能を解除